How to Build a Welded Wire Fence? Guide, Steps, Types & Tips

Published on: June 21, 2025 | Last modified: March 4, 2025

By: Tyler James

A wire fence is a type of barrier made from strands of wire. It’s commonly used for security, farming, or to contain pets.

So, how to build a welded wire fence? It’s crucial to follow the right steps to ensure durability and functionality. I once skipped a step, and the fence ended up leaning awkwardly. Trust me, getting it right makes a huge difference!

In this guide on how to build a welded wire fence, we’ll cover what a welded wire fence is, explore various types, discuss steps to construct it, look at factors that impact construction, and address frequently asked questions. You’ll get a well-rounded understanding of everything from how to make a welded wire fence to how to build a gate for welded wire fence.

Contents

- How to Build A Welded Wire Fence?

- What is a Welded Wire Fence?

- Types Of Welded Wire Fences

- Steps to Build a Welded Wire Fence

- Factors Affecting Welded Wire Fence Construction

- Common Mistakes When Building a Welded Wire Fence

- Welded Wire Fence Maintenance Tips

- Frequently Asked Questions (FAQs)

- Conclusion

- References

How to Build A Welded Wire Fence?

A wire fence is a durable barrier. To build a welded wire fence, you’ll need a 2.0 mm (0.08 In) diameter wire, concrete, and 8 cm (3 in) metal posts spaced every 2.4 m (8 Ft). It’s relatively easy, perfect for gardens or livestock.

What is a Welded Wire Fence?

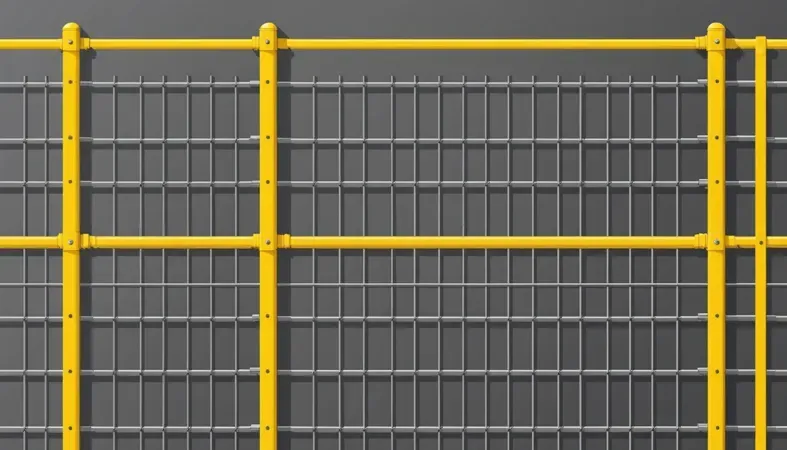

A welded wire fence is a durable structure made from intersecting steel wires welded together at each connection. The wire diameter typically ranges from 1.5 mm to 4 mm (About 0.06 To 0.16 Inches), creating a grid pattern with openings between 25 mm and 150 mm (1 to 6 Inches). These fences are often used in agricultural, residential, and industrial applications because they resist rust and corrosion effectively.

To build a welded wire fence, start with strong posts—metal or wood work well. Space your posts about 2.4 m (8 Feet) apart for stability. Using quality welded wire with a 50 mm (2-inch) grid provides a good balance of strength and visibility for livestock. Dig holes and set the posts deep to ensure your fence lasts.

I’ve used it extensively to keep my dogs safe in the yard. A welded wire fence works well because it’s sturdy yet lets them see outside. Learning how to build a welded wire fence allowed me to customize it—the height and spacing of the panels can be adjusted easily based on my needs. You can’t beat that flexibility!

Types Of Welded Wire Fences

What types of wire fences can you build?

Field Fences

Field fences are for livestock. To build one, use sturdy wooden posts. Mark your fence line and sink the posts about 2 feet (0.6 M) into the ground.

Garden Fences

Garden fences keep pests out while protecting your plants. For this, use smaller welded wire panels. Dig holes for your posts, spread gravel for drainage, and secure panels every 6-8 feet (1.8-2.4 M).

Animal Control Fences

These fences prevent animals from roaming. Use a 4-foot (1.2 M) tall welded wire. Space your posts 8-10 feet (2.4-3 M) apart and attach the wire securely, ensuring no gaps.

Chain Link Fences

Chain link fences provide visibility and security. Attach welded wire to your chain link framework. Install posts every 10 feet (3 M) and weave the wire smoothly between them.

Security Fences

Security fences deter unwanted visitors. You’ll need heavy-duty welded wire for this. Place robust steel posts every 5 feet (1.5 M) and reinforce the bottom with additional wires for strength.

We covered the various types of welded wire fences. Next, we will cover the steps to build a welded wire fence.

Steps to Build a Welded Wire Fence

Now, we’ll cover the steps to create a sturdy welded wire fence. Follow these steps closely, and you’ll succeed!

Plan Your Fence Layout

First, sketch your fence line. Measure your area with a measuring tape to ensure accuracy. Mark corners and gates clearly. If you’re using a standard height of 1.2 meters (4 Feet), plan for any dips or slopes in the land. When securing metal posts, watch out for porosity which affects weld integrity as it can compromise construction stability. Learn more about what causes porosity in welding.

Map where your posts will go, typically spaced about 2.4 meters (8 Feet) apart. Consider how corner posts will stabilize your fence. Every inch counts; improper spacing can weaken the structure!

Select Materials

Choose strong welded wire panels for your fence. A common choice is 1.9 meters (6 Feet) high wire with 50 mm (2 Inches) openings for durability. This setup works well for keeping animals in or out. Note the gauge—20 to 12 is robust enough for most applications. A crucial aspect when selecting and installing wire panels is understanding the technique for welding uphill to ensure strength and stability.

Don’t forget your posts! Wood posts work well, but for long-lasting durability, consider metal T-posts. You’ll also need concrete to set your posts firmly. This is crucial for a sturdy structure!

Prepare the Ground

Clear the fence line of vegetation and debris. Use a shovel to dig out unwanted roots or rocks. Maintaining a level, cleared area helps with construction. Mark the post positions with stakes for accuracy.

Use a level to check the ground’s evenness. Uneven ground can lead to a wobbly fence. Take your time here—it’s the foundation of your fence!

Install Fence Posts

Prepare for some dirt as you start setting the posts! Dig holes about 0.6 meters (2 Feet) deep, depending on your frost line. Place a post in each hole and fill it halfway with gravel for stability. Ensure they’re locked in tight.

Once leveled, pour concrete to fill in the post holes. Let it cure for at least 24 hours; rushing this step can lead to leaning posts. Proper installation allows your fence to stand the test of time.

Attach Welded Wire Panels

Unroll the welded wire and align it with your posts. Use U-nails or wire ties to attach each panel securely to your posts. Space these ties no more than 30 cm (12 Inches) apart for maximum hold. Be careful—overextending panels can create gaps. When welding materials like stainless steel, it’s crucial to be aware of the release of toxic substances to ensure safety in your operations.

When installing, ensure the wire is taut; this keeps the fence upright and sturdy. Taking your time here is key; you’ll thank yourself later when the fence is straight and strong.

Secure the Fence

Double-check all attachments for gaps or loose fittings. Reinforce any weak points with extra ties or wood battens. These small adjustments can make a big difference in strength.

Lastly, pull on the wire firmly and check its stability. If you have a gate, test it out! A solid fence means a secure area for pets or livestock.

That covers the process of creating a welded wire fence. Let’s now take a look at the elements influencing its construction.

Factors Affecting Welded Wire Fence Construction

What factors influence building a welded wire fence?

Terrain Conditions

Terrain affects installation. Flat land is easier than rocky or uneven surfaces, which may require more preparation.

Material Durability

Choose high-quality materials. Galvanized wire lasts over 20 years due to its corrosion resistance.

Local Regulations

Check zoning laws. Regulations may dictate height and placement for compliance.

Purpose Of the Fence

Determine its purpose. Privacy, livestock containment, or garden protection require different designs and heights.

Height Requirements

Height is crucial for effectiveness. A 4-foot (1.2 M) fence may suffice for pets, but larger animals need a minimum of 6 feet (1.8 M).

That covers the elements influencing welded wire fence construction. Let’s now take a look at typical errors in fence building.

Common Mistakes When Building a Welded Wire Fence

Let’s dive into some frequent blunders people make. Avoid these, and your fence will be stronger and last longer!

Ignoring Soil Type

Soil can shift. Avoid sandy or loose soil that won’t hold posts well. Soft soils can require deeper posts, sometimes up to 1 meter (3.3 feet).

Not Leveling the Ground

An uneven base leads to a tilting fence. You should always check the levelness—after all, nothing’s worse than a crooked fence!

Incorrect Post Height

Posts should be 1.2 meters (4 feet) above ground, at least. If they’re too short, the fence won’t serve its purpose effectively.

Using Inadequate Fasteners

Don’t skimp on fasteners. Use galvanized staples or tie wire to ensure secure attachments. Weak fasteners lead to sagging and gaps.

Neglecting Maintenance

Even welded wire needs care! Regularly check for rust or loose fasteners every year. Prevention saves you hassle down the line.

We have now covered common mistakes in building a welded wire fence. Next, we will examine maintenance tips for welded wire fences.

Welded Wire Fence Maintenance Tips

To keep your fence in top shape, remember these maintenance tips:

| Maintenance Task | Frequency | Details |

|---|---|---|

| Inspect for Rust | Annually | Look for rust spots or corrosion, especially if near moisture. |

| Tighten Loose Fittings | Every 6 Months | Check and re-tighten all fasteners to prevent sagging. |

| Clear Vegetation | Seasonally | Trim back any plants close to the fence to prevent damage. |

| Check Overall Stability | Every 6 Months | Ensure posts remain solidly set and the fence is upright. |

| Paint with Protective Coating | As Needed | Apply paint or a rust-resistant coat if signs of wear appear. |

Frequently Asked Questions (FAQs)

Now let us look at what people typically ask about wire fences.

How Far Apart Should Posts Be for Welded Wire Fence?

For a welded wire fence, you should place posts about 6 to 8 feet (1.8 To 2.4 Meters) apart. This spacing ensures adequate support and stability, especially for taller fences. If your fence is designed to hold livestock, closer spacing may be necessary for added strength and security.

How to Attach Welded Wire Fence to Wood?

You can attach welded wire fence to wood using staples or attach clips. Using 1 to 1.5-inch (2.5 To 3.8 Cm) galvanised staples will securely hold the wire in place and resist rusting. Just hammer them into the wood post at regular intervals for best results. When working in metal industries, understanding the causes of electric shock is crucial to ensure safety.

Do You Need to Stretch Welded Wire Fence?

Yes, you need to stretch welded wire fence for a sturdy installation. Stretching removes slack, preventing sagging and ensuring a tight fit along the posts. A properly tensioned fence boosts its overall durability and effectiveness in containing animals or marking boundaries.

Can You Use Welded Wire As a Fence?

Absolutely, you can use welded wire as a fence. It’s strong and durable, ideal for livestock containment and garden protection. With various thicknesses and mesh sizes, you can choose one that fits your specific fencing needs, ensuring both security and visibility.

How to Build a Gate for Welded Wire Fence?

To build a gate for a welded wire fence, start by framing the gate with 2×4 inch (5×10 Cm) lumber. Add hinges and a latch, then attach the welded wire mesh to this frame. Ensure the gate fits snugly within the gap for effective use and durability.

Conclusion

We’ve gone through a lot; thank you for sticking it out. We covered the definition of a welded wire fence, different types you can choose from, steps to build it, and factors that affect your construction. Plus, we answered some frequently asked questions to clear any doubts you might have.

So, how to build a welded wire fence? Simply gather the right materials, follow the outlined steps, and consider those factors we discussed. If you need help with any part of the process, or you’re looking for specifics like how to build a gate or welded wire panels, contact me if you’d like more guidance.

To further enhance your knowledge about welding and its applications, feel free to explore our homepage: What is Welding.

References

- American Welding Society. (2015). AWS D1.1/D1.1M: Structural Welding Code – Steel. Miami, FL: AWS.

- Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology (7th ed.). Upper Saddle River, NJ: Pearson.

Tyler is a passionate DIY welder and self-taught metal artist with years of hands-on experience transforming raw materials into functional and artistic creations. Specializing in MIG welding, Tyler crafts everything from custom furniture to outdoor sculptures, blending creativity with technical skill. Committed to making welding accessible, Tyler shares practical insights and project inspiration to help beginners and hobbyists confidently explore the world of metalworking.

Agricultural Fencing, American Welding Society, Construction, Construction Guide, Fence Building, Fence Maintenance, Pet Containment, Regulations, Welded Wire Fence, Welding, Wire Diameter