How to Weld Acrylic? Steps, Techniques, and Tips!

Published on: December 2, 2024 | Last modified: March 4, 2025

By: Joe Carter

I get asked quite often about how to weld acrylic. It’s super important to know because not following the right steps can lead to weak joints or messy seams. From my experience, a solid weld offers strength and creates a professional look.

In this guide, I’ll cover types of acrylic and their weldability, prerequisites for welding, steps to weld acrylic, essential precautions, and techniques to address common problems. Also, we’ll discuss aftercare tips, advantages of welding, and some alternatives. You’ll learn if you can weld plexiglass or polycarbonate effectively, too.

Contents

- How to Weld Acrylic?

- What is Acrylic?

- Types Of Acrylic and Their Weldability

- Prerequisites

- Essential Precautions

- Steps to Weld Acrylic

- Types Of Acrylic Welding Techniques

- Factors Affecting Acrylic Welding

- How to Address Common Acrylic Welding Problems

- Aftercare and Inspection for Welding Acrylic

- Advanced Methods and Equipment for Acrylic Welding

- Advantages Of Welding Acrylic

- Applications Across Different Fields

- Are There Any Alternatives to Welding Acrylic?

- Frequently Asked Questions (FAQs)

- Conclusion

- References

How to Weld Acrylic?

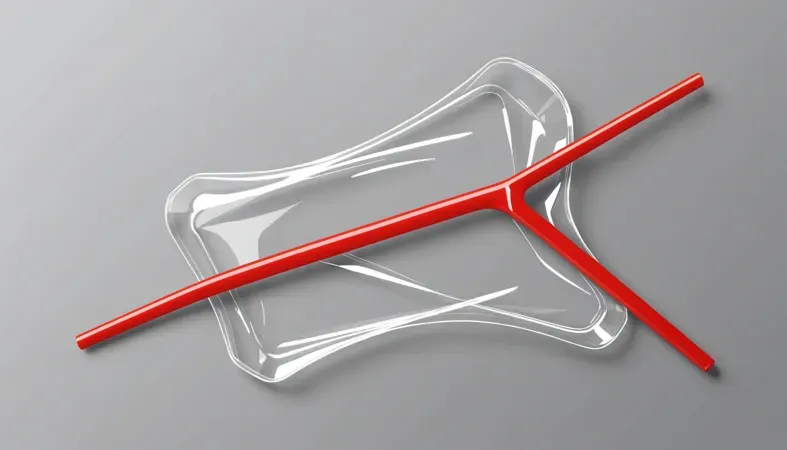

Acrylic is a clear, durable plastic used in many applications. To weld acrylic, use a heated tool at around 320°F (160°C) for effective bonding. It’s moderately difficult and common in signage and display cases.

What is Acrylic?

Acrylic, or polymethyl methacrylate (PMMA), is a versatile plastic with impressive properties. It’s lightweight, at about 1.19 g/cm³ (74.3 Lbs/ft³), and offers excellent clarity, transmitting up to 92% of light. Unlike glass, which breaks easily, acrylic is shatter-resistant, making it ideal for various applications. With a service temperature of -40°C to 80°C (-40°F to 176°F), it’s suitable for indoor and outdoor use.

When connecting acrylic pieces, knowing how to weld acrylic is essential. Joining acrylic sheets can create a solid bond that looks seamless. Many people use acrylic cement or a solvent like acetone for effective results.

A friend of mine used acrylic to create a custom display case. They were excited to see how easy it was to work with, allowing them to design any shape they wanted. Many ask, “Can you weld acrylic?” or “How do you weld acrylic sheets together?” Remember, using the right materials is key to success every time.

Types Of Acrylic and Their Weldability

What types of acrylic will you work with?

-

Cast Acrylic

Cast acrylic is made by pouring liquid acrylic into a mold. To bond cast acrylic pieces, use an acrylic cement or solvent like Weld-On 4. Clean the surfaces, apply a thin layer of cement along the edges, and press them together until set—usually around 30 minutes.

-

Extruded Acrylic

Extruded acrylic is created by feeding acrylic through a machine, producing sheets that are cheaper but less clear than cast acrylic. You can use heat welding for extruded acrylic; heat the edges with a strip heater until soft, then press together and hold until cool.

-

Impact Modified Acrylic

This type of acrylic is toughened for extra strength, making it impact-resistant. To weld it, apply an acrylic welding solvent to the edges with a brush and clamp them for 20 minutes until cured. Before welding on a vehicle, it’s crucial to know what to disconnect to prevent damage.

-

Transparent Acrylic

Transparent acrylic is clear and often used for windows and displays. Use a clear acrylic cement to bind this type. Apply the cement thinly to the edges and hold the pieces together for at least 20 minutes for a solid weld.

-

Colored Acrylic

Colored acrylic comes in various hues and is ideal for aesthetic applications. To weld colored acrylic, use the same acrylic welding glue. Clean the surfaces, apply the glue, and press firmly until it bonds, which typically takes about 30 minutes. In welding, safety precautions are crucial because one hazard is weld flash which can severely damage the eyes and skin without proper protection; you can read more on understanding weld flash.

You should now have a good understanding of different acrylic types and their weldability. In the next part, we’ll discuss prerequisites.

Prerequisites

What do you need to get started with welding acrylic?

- Acrylic Welding Solvent: You’ll need a solvent like Weld-On 4 or Acrifix 1R 0192. It’s crucial for a strong, clear bond in acrylic.

- Welding Tool: Use a hot air welder, such as the Steinel HL 2020 E. This tool provides precise heat control, essential for melting acrylic without damaging it.

- Acrylic Sheets: Get sheets like Cygnus Clear Acrylic (6.35 Mm, 1/4 Inch). This thickness is ideal for welding and offers sturdiness.

- Stencil or Tape: Use painter’s tape to mask areas. It keeps your work tidy by preventing excess weld from spreading outside the seam.

We covered necessary prerequisites for understanding the topic. Next, we will cover essential precautions to consider.

Essential Precautions

Here are vital precautions for welding acrylic.

- Wear Safety Goggles: Protect your eyes from sparks and debris. Use UV-protective goggles, like 3M’s model. They prevent eye injuries from plastics.

- Use Proper Ventilation: Weld in a well-ventilated area to reduce fumes and prevent long-term lung damage. A fan or ventilation system is helpful.

- Keep Flammable Materials Away: Clear your workspace of flammable items. Acrylic burns at around 260°C (500°F), which can trigger fires. Safety is key!

- Check Equipment Regularly: Inspect your welding tools before use. Issues can cause accidents and equipment failures. Use a checklist to stay safe.

Always prioritize safety—it’s essential for a successful project!That covers key safety measures and best practices. Let’s now take a look at the methods for welding acrylic.

Steps to Weld Acrylic

Now, let’s cover the steps to properly weld acrylic for a strong bond. Let’s dive in!

-

Prepare the Acrylic Surfaces

Start by aligning the acrylic pieces you want to join. Ensure they fit snugly together; improper alignment can weaken the bond. Use a square or straightedge to check for perfect edges. This step can save you time and frustration later.

Trim any rough edges or defects using a utility knife or fine-toothed saw. A clean edge allows for better penetration of the solvent and a stronger bond. Trust me, rough edges usually lead to leaks or weak joints.

-

Clean the Acrylic Pieces

Wipe down both surfaces with a lint-free cloth. Dust, fingerprints, or grease will prevent proper bonding. Use isopropyl alcohol (IPA) or mild soap and water for this. Ensure the surfaces are completely dry before proceeding.

Inspect the cleaned surfaces for any remaining debris. A clean surface enhances the adhesive power of the solvent. This step often makes a significant difference in the final appearance and durability.

-

Choose the Right Solvent

Select a suitable acrylic welding solvent, like acetate or butyl acrylate. These agents slightly dissolve the acrylic surface, creating a fused bond. Choose a solvent that matches the thickness of your acrylic sheets; 3-6 mm sheets often work well with acetone or specialized acrylic cement.

Not all solvents bond well or may cause cloudiness. Always test a small piece first; it’s worth avoiding a costly mistake!

-

Apply the Solvent

Using an applicator or syringe, carefully apply the solvent to the edges you want to bond. Don’t flood the acrylic; a thin layer is more effective. Let the solvent seep into the joint for 10-15 seconds to create the necessary chemical bond.

Monitor how the solvent evaporates. If it evaporates too quickly, reapply a thin layer. The goal is to achieve a consistent application without gaps. It’s all about patience; give it time to work.

-

Press and Hold the Pieces Together

Press the acrylic pieces together firmly for at least 5 to 10 minutes. A strong, steady grip creates a tight seal, essential for a strong bond. You can also use clamps or weights to hold them during this phase.

Do not let go too soon; unless you’re in a rush, allowing it to set longer yields better results. Sometimes, waiting a little longer helps avoid future failures. Good things do come to those who wait!

-

Allow to Cure

Once you’ve held the pieces together, let the bond cure. Depending on the solvent used, curing may take several hours to a full day. Avoid any movement during this time for a strong bond.

Check the manufacturer’s guidelines for precise curing times. Don’t rush this step; it pays off later with incredibly strong joints. Cutting corners here will only lead to regret.

We covered the steps for welding acrylic. Next, we will cover different techniques for acrylic welding.

Types Of Acrylic Welding Techniques

Let’s cover the types of acrylic welding: Solvent Welding, Laser Welding, Ultrasonic Welding, Thermal Welding, and Electrofusion Welding.

-

Solvent Welding

Solvent welding uses a solvent to soften and bond acrylic edges, creating a strong chemical connection. This method is one of the effective welding processes that can be used for various applications. Solvents like methyl methacrylate or chloroform are easy to apply with a brush or syringe.

Proper equipment adjustment is crucial for safety, and for that, understanding how to adjust welding helmet settings ensures effective protection.

-

Laser Welding

Laser welding employs a focused light beam to melt acrylic parts together, which falls under the category of specialized welding. It provides precision and speed with minimal thermal distortion. A laser welder can cost about $100,000, but it’s efficient for large projects.

However, achieving high-quality welds requires understanding potential issues, such as crater cracks in welding.

-

Ultrasonic Welding

Ultrasonic welding uses high-frequency vibrations to generate heat, fusing acrylic surfaces in seconds. Typical setups cost around $50,000, making it suitable for high-speed production.

-

Thermal Welding

In thermal welding, heat guns or welding rods melt acrylic parts. It’s a simple, DIY method favored by hobbyists for its accessibility and suitability for creative projects.

-

Electrofusion Welding

Electrofusion welding uses special fittings with embedded coils. When electricity flows, the fittings heat up and fuse with the pipes. This method is highly effective for large-scale installations. It’s essential to recognize that welding certain materials, like galvanized steel, can pose severe health risks due to the release of toxic fumes, which may be life-threatening. For insights on these dangers, delve into welding galvanized steel safely.

Factors Affecting Acrylic Welding

What factors affect joining acrylic sheets?

-

Temperature Control

Temperature influences acrylic’s viscosity. Maintain 90-120°C (194-248°F) for proper fusion.

-

Material Thickness

Thicker materials need more heat. For example, 10mm acrylic requires a longer weld time than 3mm.

-

Joint Design

A well-designed joint can make or break your weld. Use techniques like the “V” joint for better surface contact.

-

Cleaning Methods

Oil and dust can ruin your bond. Always clean surfaces with isopropyl alcohol for the best results.

-

Weld Time

Longer weld times create a stronger bond. Aim for at least 10-20 seconds for each inch of the joint.

How to Address Common Acrylic Welding Problems

Let’s examine issues specific to acrylic welding.

-

Bubble Formation

Acrylic often develops bubbles during welding. Inspect joints for blisters to identify them. To resolve, reduce heat sensitivity by adjusting welding speed and temperature, aiming for around 300°F (149°C).

If you’re considering working on automotive structures, you might wonder about the legal aspects of welding a car frame.

-

Weak Joints

Acrylic can form weak joints if welded improperly. Using the right adhesive and ensuring clean edges is essential. Aim for a 0.5 mm (0.02 In) gap for optimal bonding.

-

Surface Contamination

Contaminated surfaces can weaken acrylic bonds. Shine a flashlight on joints to identify dirt or oils. Clean with isopropyl alcohol before welding to ensure a strong connection.

-

Discoloration

Acrylic can discolor when overheated. Look for yellowing. To fix this, use lower heat settings and short bursts while welding, not exceeding 275°F (135°C). Preheat the surfaces as well!

Aftercare and Inspection for Welding Acrylic

Here’s advice on what to do after welding acrylic, how to check your work, and advanced techniques for experienced welders.

Aftercare Tips

After sealing your acrylic, let it cool for at least 30 minutes before handling. Store it in a dust-free environment, ideally around 20°C (68°F), to prevent contamination. Use a non-abrasive cleaner, such as specialized acrylic cleaning spray, to keep surfaces clear and scratch-free.

Inspection

Inspect joints with a magnifying glass for uneven surfaces or bubbles. Use a texture solution blending product, like Loctite Henkel 60-second epoxy, to find any flaws that may not be visible. Check light transmission by holding a flashlight against the joint to ensure clarity.

Advanced Methods and Equipment for Acrylic Welding

If you’re serious about acrylic welding, you might want to explore advanced techniques and materials that can elevate your projects.

Specialized Equipment

- Pneumatic Welding Guns: These are powerful tools that use compressed air for heat generation, offering consistent temperature control. They’re great for production environments. Prices typically start around $300.

- Fume Extractors: In an enclosed space, fume extraction is vital. These units remove harmful fumes generated during welding. Expect to invest around $500 for a quality unit.

- Infrared Heater: This tool provides even heat distribution and minimizes the risk of overheating. They’re generally priced between $200 to $600.

Additional Techniques

There are also some lesser-known methods for enhancing your acrylic welding experience:

- Pressure Welding: This combines heat with applied pressure, creating a stronger bond. It works well for high-stress applications.

- Ribbed or Grooved Joints: These designs increase surface area for the adhesive bond. Consider using a router to achieve this effect.

- Edge Preheating: Preheating edges to around 70°C (158°F) improves adhesive flow and bonding strength, especially on thicker acrylic sheets.

Table of Advanced Equipment and Uses

| Equipment Type | Use | Approx. Cost ($) |

|---|---|---|

| Pneumatic Welding Gun | Consistent heat for production | 300+ |

| Fume Extractor | Removal of harmful fumes | 500 |

| Infrared Heater | Even heat distribution | 200 – 600 |

Advantages Of Welding Acrylic

The main benefit of welding acrylic is its durability. A friend of mine used it for a custom display case, and it turned out strong and clear. Moreover, it provides a seamless finish, is waterproof, resistant to UV light, cost-effective compared to glass, and lightweight, making it easy to work with. To achieve optimal welds, selecting the correct welding wire size ensures structural integrity and the best finish when working with different materials. For more information on choosing the right wire, explore what size wire for a welder.

Applications Across Different Fields

Acrylic is commonly used for display cases and has various applications, including:

- Aquarium Construction: Acrylic works well for making aquariums due to its clarity and durability. It allows for larger sizes than glass and is popular for custom tanks.

- Signage: In advertising, acrylic welding creates vibrant and durable signs. Its flexibility and ease of cutting make it ideal for indoor and outdoor use.

- Medical Devices: Acrylic is often used in medical applications for its lightweight and strong properties. It’s found in tools, trays, and equipment housings, ensuring easy sterilization.

- Art Installations: Artists frequently use welded acrylic for sculptures and installations. Its transparency and modern appearance provide unique aesthetics, merging creativity with strong engineering.

Are There Any Alternatives to Welding Acrylic?

There are definitely alternatives that you can use to bond acrylic. Products such as acrylic cement and acetone work well for joining sheets without a welding process. Through trial and error, I’ve discovered that these options can often save time and require less skill than traditional welding.

If you’re looking for another route, consider using acrylic welding glue like Acrylic Weld 4. This adhesive is a solid choice for getting a strong hold and works great for different setups. Whether you’re assembling displays or crafting projects, these methods can achieve a clean finish, just like when welding acrylic.

Frequently Asked Questions (FAQs)

We have covered some questions about welding acrylic. I typically get asked the following:

What is the Strongest Way to Bond Acrylic?

The strongest way to bond acrylic is using solvent welding. This method creates a molecular bond between acrylic pieces. With proper application, it can reach a tensile strength of up to 10,500 psi (72.5 Mpa), making it ideal for durable joints.

What Are Two Methods Of Joining Acrylic?

Two methods of joining acrylic are solvent welding and mechanical fastening. Solvent welding uses a chemical solvent for a smooth finish. Mechanical fastening involves screws or plates, which can be less aesthetically pleasing but effective in structural support.

Can Acetone Be Used to Weld Acrylic?

Yes, acetone can be used to weld acrylic. It acts as a solvent, softening the acrylic to create a strong bond. However, be cautious—using too much acetone may deform the pieces, ruining the joint. Understanding the intricacies of different welding techniques can enhance your approach especially when learning about welding thermocouple wire.

Can Acrylic Be Heat Welded?

Yes, acrylic can be heat welded using a hot air or hot tool method. This technique melts the surfaces to create a joint. Seal strengths can reach up to 90% of original material strength when done correctly.

Can You Weld Polycarbonate?

Yes, you can weld polycarbonate using various methods, including solvent bonding and thermal welding. Polycarbonate welding offers high impact resistance. Tensile strengths can exceed 9,000 psi (62 Mpa) depending on the method used.

Can You Weld Plexiglass Together?

Yes, you can weld Plexiglass together. Plexiglass welding can be done using solvent welding, which provides a clear and strong joint. Joining techniques differ, but tensile strength can still reach similar levels to acrylic, around 7,000 psi (48.3 Mpa).

Conclusion

I’m glad we could cover this together. We discussed various critical items on how to weld acrylic, including what acrylic is, its types and weldability, prerequisites, steps, essential precautions, welding techniques, factors affecting welding, common problems, and aftercare. Additionally, I highlighted the advantages of welding acrylic and its applications across different industries.

I trust these insights have been helpful in answering the question of how to weld acrylic. To put it simply, you need to know the type of acrylic, prepare properly, apply the right welding techniques, and address any common issues effectively. By following these steps and precautions, you’ll attain a strong, clean weld every time.

For further exploration of the world of welding, be sure to check out What is Welding for more in-depth welding guides and tutorials.

References

- ISO. (2017). ISO 3834: Quality Requirements for Fusion Welding of Metallic Materials. Geneva, Switzerland: ISO.

- American Welding Society. (2015). AWS D1.1/D1.1M: Structural Welding Code – Steel. Miami, FL: AWS.

Joe Carter is a retired welding professional with over 40 years of hands-on experience in the industry, spanning ship repair, structural welding, and even underwater projects. Joe is a master of MIG, TIG, and Stick welding. Passionate about mentoring the next generation of welders, Joe now shares his decades of expertise and practical insights to help others build rewarding careers in welding.

Acrylic, Acrylic Cement, American Welding Society, DIY Projects, Plastic Fabrication, Safety Precautions, Structural Integrity, Welding, Welding Techniques, Welding Wire