How Much Are Welding Rods? Pricing, Types, and Key Factors

Published on: November 20, 2024 | Last modified: December 20, 2024

By: Joe Carter

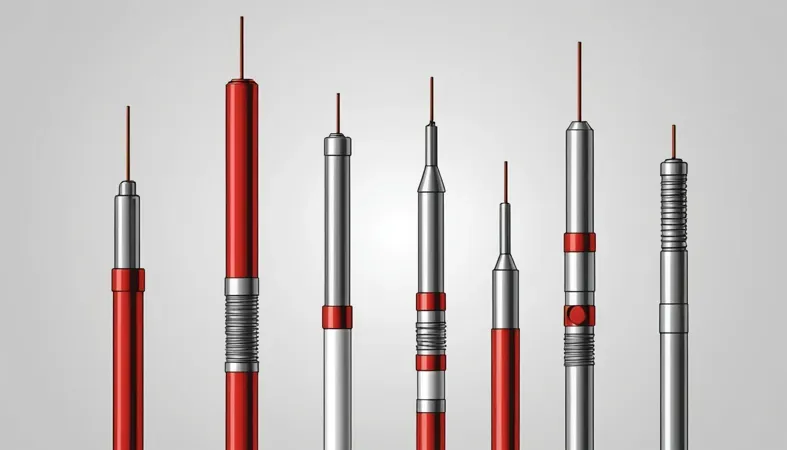

Welding rods are small, cylindrical pieces used in the welding process. They help join metals together by melting during the welding operation.

You may ask, how much are welding rods? It’s crucial to know their price and quality before buying. I’ve learned that the cost can affect your project budget, and poor-quality rods can lead to weak joints and expensive fixes.

In this guide, I’ll cover what welding rods are, the various types, steps for choosing the right ones, factors that influence their cost, and frequently asked questions related to welding rods, including what is a welding rod and can welding rods go bad.

Contents

How Much Are Welding Rods?

Welding rods are consumable materials for joining metals during welding. So, how much are welding rods? They typically cost between $5 to $50 per pound (0.45 Kg), depending on type and application, like stick or TIG welding.

What Are Welding Rods?

Welding rods are essential in the welding process. They serve as filler materials, adding strength and integrity to the joint. Typically, these rods range from 2.0 mm to 6.4 mm (0.08 Inches to 0.25 Inches) in diameter. You can find them made from various materials, like steel, nickel, or aluminum, to suit different welding applications.

Now, let’s discuss welding rod prices. They can vary widely depending on type and size. For instance, a box of 10 steel welding rods may cost $15 to $40 or more, depending on your specific needs and quality.

A friend used 7018 welding rods for thick steel joints. He shared how crucial the right rod is for a strong weld. If you’re looking into welding rods, knowing their costs can save you money in the long run. Quality matters to ensure your jobs are secure and lasting.

Types Of Welding Rods

What types of welding rods are available?

Mild Steel Welding Rods

Mild steel welding rods are ideal for general applications. Prices range from $1 to $3 (USD) per rod, depending on the brand and size. Check local stores like Home Depot or Lowe’s for bulk pricing or box deals.

Stainless Steel Welding Rods

These rods are designed for strength in corrosive environments. They typically cost between $2 and $5 (USD) each. To save money, consider buying them online or in material packs.

Aluminum Welding Rods

Aluminum rods are excellent for lightweight jobs. Expect to pay around $3 to $6 (USD) per rod. For lower costs, look for all-in-one kits that include rods and additional supplies.

TIG (Tungsten Inert Gas) Welding Rods

TIG rods offer precision and quality. They usually cost between $2 and $10 (USD) each, depending on the type and length. Buy in bulk or from specialized welding supply stores for better prices.

MIG (Metal Inert Gas) Welding Rods

MIG rods are fast and efficient for thicker materials. They generally cost between $1 and $3 (USD) per rod. Look for multi-packs to save on quantity discounts.

That covers the various types of welding rods. Let’s now take a look at how to select the right rods.

Steps for Choosing Welding Rods

Here are steps to help you determine the cost of welding rods and choose the best options.

Determine Your Project Requirements

Identify the specifics of your project. Know the materials you’ll be welding and their thickness. For instance, if you’re welding steel that’s 1/4 inch (6.35 Mm) thick, consider a higher amperage rod like the 7018 type. I remember forgetting to check the thickness when I first welded, and my welds suffered! For mastering different welding positions, you might want to explore these .

Consider joint type and desired weld strength. A mild steel rod costs around $5 to $7 (About €4.50 To €6.50) per pound (0.45 Kg). Don’t skip this step; choosing the wrong rod can lead to added expenses for rework. If you are looking to enhance your welding skills, mastering could be your next step.

Research Welding Rod Types

Explore different types of welding rods. Common types include 6011, 6013, and 7018, each with specific uses. For example, 6011 is ideal for welding dirty or rusty surfaces. Mixing up rod types can significantly affect welding quality! Mastering the intricacies of welding techniques can elevate your skills, and discovering adds to your expertise.

Check suppliers like Home Depot or Lowe’s for inventory and pricing. Prices range from $0.50 to $10 (About €0.45 To €9) each, depending on type and size. Know which rods work best for your materials to maximize value. You can also learn more about for additional technical precision in your projects.

Calculate the Amount Of Welding Rods Needed

Estimate how many rods you’ll need based on project size. A general rule is about 2 to 3 rods for every hour of welding. For instance, if your project requires 10 hours of welding, budget for around 20 to 30 rods. I can’t stress how important it is to overestimate; running short midway through is frustrating!

Additionally, when considering welding techniques, learning can significantly impact material usage and efficiency.

When calculating costs, include all expenses. If each rod averages around $5 (About €4.50), for 30 rods, you’ll need about $150 (Around €135). Having an accurate count can save you from last-minute scrambles.

Check Local Suppliers and Compare Prices

Visit local suppliers or check online for the best rod prices. Prices can fluctuate between stores like Lowe’s and Home Depot. One store might offer better prices for the same rods or have bulk purchase deals!

When you find a price, call around or check online reviews. Spending a few minutes comparing prices can lead to significant savings. I’ve scored great discounts by taking the time to shop around!

You should now have a good understanding of selecting welding rods. In the next part, we’ll discuss price comparisons of welding rods.

Comparative Price Analysis of Welding Rods

Understanding the price differences can help you make an informed choice.

| Welding Rod Type | Price Range (USD) | Typical Uses | Approx. Rod Length (inches) |

|---|---|---|---|

| Mild Steel (E6011) | $1 – $3 each | General welding applications | 12 – 14 |

| Stainless Steel (E309) | $2 – $5 each | Corrosive environments | 12 – 14 |

| Aluminum (4047) | $3 – $6 each | Lightweight jobs | 12 – 14 |

| TIG (Thoriated) | $2 – $10 each | Precision welding | 10 – 36 |

| MIG (ER70S-6) | $0.50 – $2 each | Thicker materials | 10 – 12 |

We have now covered the comparative pricing of welding rods. Next, we will examine the factors that affect welding rod costs.

Factors Influencing Welding Rod Costs

What factors affect welding rod pricing?

Type Of Welding Rod

Different welding rod types, such as 7018 and 6013, vary in cost due to their specifications. For instance, a 1/8 inch (3.2 Mm) 7018 rod typically costs $2.50 to $4.00 each, while a 6013 rod can be as low as $0.75. It is essential to source quality metals from reliable vendors for welding projects, and you may find helpful resources on .

Supplier Pricing

Each supplier has a unique pricing structure that affects overall costs. Local suppliers may charge more due to shipping expenses, while larger chains like Home Depot often offer competitive prices.

Material Availability

Shortages in raw materials can raise prices. If a specific alloy is in high demand but low supply, expect welding rod prices to increase significantly.

Brand Reputation

Brands with strong reputations often charge higher prices for their welding rods. While you might pay more, they typically provide better quality and performance.

Quantity Purchased

Buying welding rods in bulk can lead to significant savings. For example, purchasing a box of 50 rods can reduce the cost per rod by up to 20% compared to buying them individually.

We have now covered the factors affecting welding rod costs. Next, we will examine strategies for finding welding rod discounts.

Tips for Finding Deals on Welding Rods

Want to save some bucks?

- Buy in bulk – Most suppliers offer discounts for larger orders.

- Check online marketplaces – Sometimes you’ll find deals that local stores don’t offer.

- Sign up for email newsletters – Suppliers often send out promos and discounts.

- Join welding forums – Members often share sales or manufacturer discounts.

Frequently Asked Questions (FAQs)

Now let us look at some common questions I typically get asked.

What is a Welding Rod?

A welding rod is a filler metal that you use during the welding process. Typically made from steel or other metals, it helps join two pieces together. Different types of welding rods are designed for specific applications, ensuring strong bonds in your projects.

When it comes to materials, techniques for require precision and skill due to the risk of burn-through.

Can Welding Rods Go Bad?

Yes, welding rods can go bad over time. They may absorb moisture, which affects their performance. If stored in a damp environment, the rods can rust and become ineffective, leading to weak welds.

What Are Welding Rods Used for?

Welding rods are used to create strong joints between metal parts. You’ll find them in various welding processes like MIG, TIG, and stick welding. Each type serves a different purpose, depending on the materials and conditions of your weld.

What is the Smallest Welding Rod?

The smallest commonly used welding rod is around 1.6 mm (1/16 Inch). Smaller rods are great for detailed work or thin sections. Using the right size ensures better control and a cleaner weld.

What Welding Rod Should a Beginner Use?

If you’re a beginner, I recommend starting with an E6011 or E6013 rod. These rods offer good versatility and are easy to use. They provide a smooth arc, which makes them perfect for various welding tasks as you learn.

In welding, understanding the causes of issues like spatter is crucial for improving your technique and results. Learn about what causes weld spatter to refine your skills and enhance your welding outcomes.

How Much Welding Rod Do I Need?

The amount of welding rod you’ll need depends on your project’s size. As a rule of thumb, for every 1 kg (2.2 Lbs) of weld, you’ll require about 1 kg (2.2 Lbs) of welding rod. Always consider the joint type and thickness when calculating.

Safety in welding also involves understanding the health risks to minimize them effectively including measures to .

How Many Welding Rods Are in a 10 Pound Box?

You’ll find around 40 to 60 welding rods in a 10-pound box, depending on the rod’s diameter. For example, 3/32 inch rods typically have more in a box than 1/8 inch rods. Knowing this helps in project planning and budgeting.

Understanding the materials used in welding rods is crucial for selecting the right type for your project. Learn about to make informed decisions.

Conclusion

We covered several key topics: the meaning of welding rods, various types of welding rods, steps for choosing the right one, and factors that influence costs. We also looked at frequently asked questions like what constitutes a good welding rod and if these rods can go bad. It’s important to grasp how these items fit together in your welding projects.

Happy to wrap things up, let’s revisit the question: how much are welding rods? Prices typically range from $5 to $50 per pound (2.27 Kg), depending on the type. Remember, specific qualities like the rod composition, such as nickel or 5P rods, and intended use affect the final cost.

For further insights into the world of welding, be sure to check out What is Welding.

References

- American Welding Society. (2020). AWS Welding Handbook: Welding Science and Technology (Vol. 1). Miami, FL: AWS.

- Occupational Safety and Health Administration (OSHA): Welding, Cutting, and Brazing: https://www.osha.gov/welding-cutting-brazing

Joe Carter is a retired welding professional with over 40 years of hands-on experience in the industry, spanning ship repair, structural welding, and even underwater projects. Joe is a master of MIG, TIG, and Stick welding. Passionate about mentoring the next generation of welders, Joe now shares his decades of expertise and practical insights to help others build rewarding careers in welding.

Welding Equipment, Welding Rods