How Long Can You Be an Underwater Welder? Key Facts, Types, and Tips

Published on: April 9, 2025 | Last modified: March 4, 2025

By: Tyler James

An underwater welder is a professional who performs welding tasks beneath the water’s surface. They use specialized equipment to join metal components in challenging underwater environments.

One question I was asked a lot is how long can you be an underwater welder. It’s crucial to know, as factors like health, training, and even life expectancy come into play. In my experience, the journey of underwater welding involves many unique challenges that can affect your career span.

In this article, we’ll cover how to start as an underwater welder, types of underwater welders, necessary steps to become one, essential precautions, unique challenges in the field, and insights into aftercare, inspection, and advanced techniques. We’ll also explore the benefits, typical applications, and alternatives to underwater welding. You’ll find valuable information relevant to how long you can underwater weld, along with practical advice for a rewarding career.

Contents

- How Long Can You Be an Underwater Welder?

- What is an Underwater Welder?

- Types Of Underwater Welders

- Before You Start (Prerequisites)

- Steps for Becoming an Underwater Welder

- Precautions

- Types Of Practices for Underwater Welding

- Factors Affecting Underwater Welding Duration

- Issues Unique to Underwater Welders

- Aftercare, Inspection, and Advanced Tips

- Benefits

- Typical Applications

- What Are Alternatives to Underwater Welding?

- Frequently Asked Questions (FAQs)

- Conclusion

- Additional Reading

How Long Can You Be an Underwater Welder?

An underwater welder works beneath the surface, often in tough conditions. You can typically work for 20-30 years, depending on training and health. The job’s risks and hazards can impact longevity and often involves offshore construction or repair tasks.

What is an Underwater Welder?

An underwater welder is a skilled professional who performs welding and related tasks underwater, typically at depths of up to 1,500 ft (457 M). They work on structures like bridges, pipelines, and ships. The welding process can be accomplished using two main techniques: wet welding and dry welding. Wet welding employs conventional welding equipment, while dry welding uses a habitat (Enclosed Workspace) to keep water away from the work area.

How long can you be an underwater welder? This job demands physical and mental stamina. I’ve seen how diving schedules and physical fitness requirements can dictate a welder’s career length. Many welders focus on sharpening their skills to avoid burnout.

I found it helpful to understand how underwater welding impacts your lifespan. Diving under pressure and exposure to hazardous environments can be tough on the body. I remember a fellow welder who faced decreasing stamina after years in the field – it really makes you think about how long you can stay in this profession. Staying fit and having regular check-ups can help extend your career.

Types Of Underwater Welders

What are the types of underwater welders, and how long can they work in this field?

-

Commercial Underwater Welders

Commercial underwater welders work on pipelines and underwater structures. You can work for about 5 to 10 years in this role. To maintain your health, it’s key to have regular medical checks and monitor your diving time to avoid decompression sickness. Understanding how to weld safely, especially with different materials, is crucial for long-term success, and you can learn to weld sheet metal efficiently.

-

Military Underwater Welders

Military underwater welders support naval operations and underwater repairs. Generally, you can serve in this role for about 4 to 8 years. To keep your skills sharp, you must complete specialized training and prepare for intense deployments. One crucial aspect of mastering advanced techniques involves understanding what a hot pass in welding entails.

-

Scientific Underwater Welders

Scientific underwater welders work in research settings. You might be in this role for 6 to 12 years. To extend your career, ongoing education in marine science and safety practices is essential, along with networking in research circles.

The ability to accurately weld thin metal can significantly enhance your skill set, ensuring precision in complex underwater projects.

-

Hyperbaric Underwater Welders

Hyperbaric underwater welders operate in high-pressure environments. Their career can last between 3 to 7 years. To maximize your work life, you need rigorous training in hyperbaric medicine and the use of special equipment to handle pressure changes safely. Another essential skill is mastering various welding techniques, including the principles of seam welding.

-

Deep Sea Underwater Welders

Deep sea underwater welders tackle challenging jobs at extreme depths. You might work for about 5 to 10 years, depending on your physical fitness. To prolong your career, strictly adhere to safety protocols and undergo frequent physical assessments. A key skill to master in this field is the ability to weld in vertical positions effectively and safely.

We’ve wrapped up the different types of underwater welders here. Next up, we’ll look at what you need to begin.

Before You Start (Prerequisites)

What do you need to be an underwater welder?

- High-Quality Diving Suit: You’ll need a suit like the LavaCore Thermal Diving Suit. It’s essential for warmth and protection during deep dives, as temperatures can drop to 4°C (39°F).

- Welding Equipment: You’ll need equipment such as the Lincoln Electric K3470-1 SuitCase X-TREME 12, a portable welder that provides reliable, high-quality welds underwater, ensuring durability.

- Specialized Scuba Equipment: You’ll need items like the Aqua Lung Phantom Scuba Diving Gear. It offers enhanced safety and comfort, allowing divers to stay underwater longer with an air tank capacity of 80 cu ft (2,265 L).

- Underwater Welding Helmet: You’ll need a helmet like the Miller Electric 04301. This helmet lets you see clearly while protecting your eyes from the harsh environment and electric arcs.

So far we covered the necessary prerequisites for diving into underwater welding. Next, let’s look at the steps to become an underwater welder.

Steps for Becoming an Underwater Welder

Here are the essential steps for understanding how long you can work as an underwater welder.

-

Complete Required Education

Finish high school or get your GED. Most employers expect at least a high school diploma since underwater welders need strong foundations in math and physics. Consider taking welding courses in school for a head start. Research community colleges or technical schools that offer welding career guidance; these often provide valuable hands-on experience.

When learning welding, understanding the compatibility of different materials is crucial, such as welding zinc-plated steel.

-

Attend Welding Training Programs

Enroll in a welding training program to learn techniques and safety measures. Look for programs accredited by the American Welding Society (AWS). A typical program lasts from 6 months to 2 years, depending on your desired level of expertise. Choose programs that offer substantial lab work for hands-on welding practice.

-

Obtain SCUBA Certification

Next, get your SCUBA certification through an accredited diving school. This certification typically takes about 2-4 weeks and is vital for deep-sea diving. You’ll learn about pressure adjustments and how to manage equipment underwater. Diving with experienced instructors can boost your confidence while diving.

-

Gain Experience Through Apprenticeships

Apply for apprenticeships to connect classroom training with real-world experience. Apprenticeships last from 1 to 4 years, depending on your skill and dedication. You’ll work under a seasoned underwater welder, learning proper techniques and how to manage stressful situations underwater. This hands-on training is invaluable for honing your skills.

-

Acquire Underwater Welding Certification

Finally, obtain your underwater welding certification, which shows you’re ready for employment in this challenging field. A certification program may take an additional 6-12 months, during which you’ll learn specific underwater welding processes and pass practical assessments. With this certification, you’ll significantly enhance your career longevity as an underwater welder.

We’ve wrapped up the steps for becoming an underwater welder. Next up, we’ll look at important precautions.

Precautions

Let’s cover essential safety measures for underwater welding.

- Monitor Dive Time: Track your session and limit it to under 90 minutes to prevent decompression sickness. I recommend using a diving computer like the Suunto Zoop Novo.

- Maintain Strong Equipment: Regularly check your gear for defects; a faulty suit can be fatal. Use reliable brands like Aqua Lung for protection.

- Get Health Checks: Regular physical exams help catch medical issues early, so don’t skip them. I’ve seen divers ignore this, and it ends badly.

- Communicate Clearly: Establish hand signals with your buddy; miscommunication can cause serious accidents underwater. Use an agreed-upon set for every dive.

Staying safe is vital in underwater welding. I care about your well-being!

Types Of Practices for Underwater Welding

Let’s cover the types: Shielded Metal Arc Welding (SMAW), Tungsten Inert Gas Welding (TIG), Metal Inert Gas Welding (MIG), Plasma Arc Welding (PAW), and Friction Stir Welding (FSW).

-

Shielded Metal Arc Welding (SMAW)

SMAW, or stick welding, uses a consumable electrode coated in flux. It’s simple and effective underwater. You can often use SMAW in low-visibility conditions, but it requires skill. An experienced underwater welder can manage this type of weld with ease.

-

Tungsten Inert Gas Welding (TIG)

TIG welding offers precision with a non-consumable tungsten electrode. It’s ideal for thin metals and produces high-quality welds. However, underwater welding with TIG can be slow, demanding more control and patience—it’s best suited for seasoned professionals.

-

Metal Inert Gas Welding (MIG)

MIG welding is faster and uses a continuous wire feed as an electrode. It’s easier for beginners and quicker than TIG. Many underwater welders choose MIG for efficiency; you can typically perform this type of welding for several hours a day.

-

Plasma Arc Welding (PAW)

PAW is similar to TIG but uses a constricted arc, creating a hotter and more focused weld. If you’re wondering how long you can be an underwater welder with PAW, note this approach requires high skill and specific equipment, making it best for advanced welders.

-

Friction Stir Welding (FSW)

FSW joins materials without melting them, using a rotating tool. It requires less post-weld processing and works well on thick materials. Although it’s a newer method, with proper training, an underwater welder can effectively use this technique over the years.

That covers the different types of techniques for underwater welding. Let’s now take a look at the factors influencing welding duration.

Factors Affecting Underwater Welding Duration

What factors influence the time you spend as an underwater welder? Here are key points to consider.

-

Depth Of Underwater Work

Working at greater depths significantly increases pressure, affecting how long you can weld. For example, at 30 meters (98 Feet), the pressure reaches 4 times normal atmospheric pressure, which can strain the human body.

-

Type Of Welding Technique

Different welding methods have varying durations and effects. Shielded metal arc welding is quick but can require more extensive repairs than TIG (Tungsten Inert Gas) welding, which may take longer but is cleaner and typically needs less rework.

-

Experience Of Welder

Your experience level greatly influences your ability to work underwater. Experienced welders can usually work up to 6 hours at depths of about 20 meters (66 Feet) without severe fatigue, while novices may only last 3-4 hours.

-

Environmental Conditions

Harsh conditions, such as strong currents or murky waters, can significantly reduce welding time. For instance, in water with visibility under 1 meter (3.3 feet), your efficiency decreases, making tasks take longer to complete. Understanding how these factors affect different fields is crucial, especially in welding by industry.

-

Equipment Used

Your gear is crucial. High-quality helmets and suits protect you, allowing for longer work periods. The weight of your gear also impacts your stamina; lighter gear results in less fatigue.

So far in this section we covered the factors that influence how long underwater welding takes. In the next section we will talk about challenges specific to underwater welders.

Issues Unique to Underwater Welders

Here are some critical challenges underwater welders face.

-

Pressure-related Injuries

Underwater welders may experience barotrauma due to pressure changes. Monitor air consumption closely and use dive tables to manage ascents and descents safely.

-

Visibility Challenges

Underwater welders often struggle with low visibility. Darkness and murkiness hinder sight. Using brighter lights (Over 1000 Lumens) can significantly improve visibility, based on my experience.

-

Equipment Malfunction

Underwater welders must be aware of gear failure risks. Regularly check welding leads and suit seals. Routine maintenance can save lives.

-

Thermal Regulation Issues

Underwater welders must combat extreme cold. Insulated wetsuits or drysuits should maintain proper temperature. Temperatures below 10°C (50°F) can be dangerous without proper gear.

-

Cutting and Welding in Currents

Underwater welders face strong currents. Adjust techniques to maintain stability, and use tethers or anchor points to avoid being swept away.

We covered the challenges faced by underwater welders. Next, we will cover aftercare, inspection, and advanced tips.

Aftercare, Inspection, and Advanced Tips

Here’s crucial aftercare information, inspection details, and expert tips for underwater welding.

Aftercare Tips

After working as an underwater welder, rinse your gear with fresh water. Saltwater can corrode your equipment, affecting long-term performance. Soak your suit in a 10% vinegar solution for 30 minutes to combat odors and grime.

Inspection

Inspect your helmet frequently, especially the face seals and visor for scratches. Use products like Miller Electric’s reduction visor to avoid fatigue while welding at depths over 30 m (98 Ft). Also, document your tool’s condition—check cables and regulators weekly to ensure everything’s operational.

Expert Tips

Here’s a pro tip: always pre-load your oxygen valves to the correct psi—between 2 bar (29 Psi)—to optimize efficiency. Fine-tuning your arc can significantly enhance quality; try adjusting your standoff to around 18 mm (0.7 In). Lastly, don’t underestimate redundancy; have a backup breathing apparatus on hand before starting a dive.

Benefits

The main benefit of knowing how long you can work as an underwater welder is job security. This knowledge helps me plan my career goals and stay focused in this competitive field.

Additionally, you’ll enjoy various perks, like high earning potential, unique adventure experiences, skill development, and job variety. Plus, the underwater welding community is supportive and tight-knit; it feels great to connect with others in this specialized trade.

Typical Applications

Underwater welding has various applications, including:

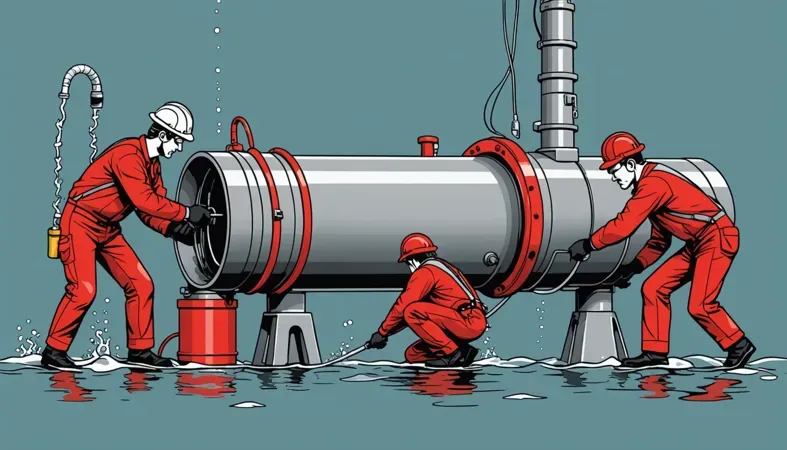

- Pipeline Repairs: Underwater welders fix damaged pipelines, ensuring they safely transport oil or gas. This job’s crucial due to the significant impact of leaks on the environment.

- Shipbuilding: Building and repairing ships requires underwater welders to maintain strong joints in submerged sections. It’s vital for ship safety and a popular specialty.

- Marine Construction: They construct docks and platforms. This specialty is popular because it allows building marine projects that need waterproof joints.

- Bridge Inspections: Inspecting underwater bridge components helps prevent collapses. This important safety task contributes to lasting structures.

What Are Alternatives to Underwater Welding?

You can explore various methods to achieve similar results without diving into the depths. For instance, remote-operated vehicles (Rovs) like the VideoRay Pro 4 deliver visual inspection and minor repairs underwater. Based on my observations and experiences, these tools are preferred for safety when dealing with complex structures or hazardous conditions.

Another option is using hyperbaric welding techniques, which take place in a controlled environment. This method reduces risks associated with underwater welding and can extend the working life of welders. They often employ products like the Hyperbaric Welding System, enabling tasks at greater depths with added safety. When discussing safety, it’s essential to consider what toxic substances are released when welding stainless steel, as understanding these risks is crucial for health and safety in welding environments.

Frequently Asked Questions (FAQs)

Now let us look at some common questions I typically get asked about underwater welding.

How Long Can Underwater Welders Work?

Underwater welders can typically work for 4 to 6 hours per dive. This duration is due to the physical demands and the need for decompression after diving. Divers must adhere to safety guidelines to reduce the risk of decompression sickness.

Do Underwater Welders Make $100 an Hour?

Yes, underwater welders can make around $100 per hour, depending on experience and location. Highly skilled welders in certain regions can earn even more, sometimes exceeding $200 per hour for specialized jobs.

How Far Do Underwater Welders Go?

Underwater welders often work at depths ranging from 10 to 300 feet (3 to 91 M). The depth depends on the project requirements and environmental conditions, impacting their safety and working time.

How Often Do Underwater Welders Work?

Underwater welders usually work on a rotating schedule, often spending several weeks working followed by days or weeks off. This allows them to recover from the physical and mental strains of deep-sea work.

How Many Years Does Underwater Welding Take Off Your Life?

Studies suggest underwater welding can reduce life expectancy due to the risks involved, including pressure-related health issues. On average, some sources estimate a potential decrease of 5 to 10 years in life expectancy for welders who dive regularly.

Conclusion

We covered what being an underwater welder means, the different types of underwater welders, prerequisites needed before you start, steps to become one, precautions for safety, practices specific to underwater welding, factors affecting your diving duration, unique challenges underwater welders face, aftercare, inspection, and tips to excel, the benefits of the job, typical applications, and alternatives to underwater welding.

So, how long can you be an underwater welder? You can usually work underwater between 5 to 10 years, depending on conditions like age, health, and lifestyle factors. I hope these welding tips prove valuable to you as you consider a career in underwater welding.

If you’re eager to expand your knowledge about welding techniques further, check out What is Welding.

Additional Reading

- American Welding Society. (2020). AWS Welding Handbook: Welding Science and Technology (Vol. 1). Miami, FL: AWS.

- Welding Institute (TWI): https://www.twi-global.com

- Parmar, R. S. (1997). Welding Engineering and Technology. New Delhi, India: Khanna Publishers.

Tyler is a passionate DIY welder and self-taught metal artist with years of hands-on experience transforming raw materials into functional and artistic creations. Specializing in MIG welding, Tyler crafts everything from custom furniture to outdoor sculptures, blending creativity with technical skill. Committed to making welding accessible, Tyler shares practical insights and project inspiration to help beginners and hobbyists confidently explore the world of metalworking.

American Welding Society, Career In Welding, Commercial Divers, MIG Welding, Safety Precautions, Underwater Welder Training, Underwater Welding, Welding, Welding Equipment, Welding Techniques