Can JB Weld Clear Weld? A Guide to Understanding Its Applications and Effectiveness

Published on: November 21, 2024 | Last modified: March 4, 2025

By: Mark Carter

JB Weld is a strong epoxy adhesive. It’s known for fixing metal and other materials effectively.

I’ve been asked many times, can jb weld clear weld? It’s crucial to know the right products and methods when tackling repairs. My experiences have shown that proper application makes all the difference in getting a strong, lasting bond.

In this guide, I’ll cover what JB Weld is, the types related to clear welding, preparation steps, essential precautions, and factors that affect performance. You’ll find common issues and troubleshooting tips, plus aftercare recommendations. Lastly, I’ll discuss the benefits of JB Weld and its applications, helping you understand how good is JB Weld for your projects.

Contents

- Can JB Weld Clear Weld?

- What is JB Weld?

- Types Of JB Weld in Context Of Can JB Weld Clear Weld

- Prerequisites

- Steps to Prepare and Apply JB Weld Clear Weld

- Precautions

- Types Of Clear Bonding Products

- Factors Affecting JB Weld Clear Weld Performance

- Common Issues You Might Encounter

- Aftercare, Inspection, and Advanced Tips for JB Weld Clear Weld

- Benefits Of Using JB Weld Clear Weld

- Applications Of JB Weld Clear Weld

- Other Options You Can Consider

- Comparing JB Weld Clear Weld with Other Clear Adhesives

- Frequently Asked Questions (FAQs)

- Conclusion

- References

Can JB Weld Clear Weld?

Yes, JB Weld can clear weld, but it’s tricky. The clarity depends on surface prep and application. For best results, clean surfaces well and apply thin layers. Let it cure fully for a strong bond.

What is JB Weld?

JB Weld is a two-part epoxy adhesive known for its strength. It consists of a resin and a hardener, which, when mixed, create a tough bond. It can withstand temperatures up to 500°F (260°C) in the cured state and handle pressures of about 3,960 psi (27.3 Mpa).

Now, let’s discuss a common question: can JB Weld clear weld? JB Weld’s clear version allows for transparent applications. You can fill gaps and make repairs without visible seams, which is ideal for projects where appearance matters.

I used it to fix a couple of clear plastic parts on an old appliance. I was amazed at how JB Weld holds non-porous materials together. Known for its versatility, it works on various surfaces—including metal, wood, and ceramics—making it a go-to choice for many DIY enthusiasts.

Types Of JB Weld in Context Of Can JB Weld Clear Weld

-

JB Weld Original

JB Weld Original is a strong epoxy that securely bonds metals. It won’t provide clear weld as effectively, but it’s great for tough repairs. To use, mix equal parts of resin and hardener, then apply to clean surfaces. Let it cure for 15-24 hours for full strength.

-

JB Weld Kwik

JB Weld Kwik is a fast-setting epoxy that quickly completes strong repairs. It doesn’t offer the clear weld finish you might want. To apply, mix equal parts and use within 5 minutes. It sets in about 4-6 hours.

For those interested in traditional metal joining methods to achieve a seamless finish, exploring how to forge weld can provide a deeper understanding of this time-honored technique.

-

JB Weld Clear Weld

JB Weld Clear Weld is designed for invisible repairs on surfaces like glass and clear plastics. Yes, it effectively works for clear welding. To use, mix equal parts of resin and hardener, then apply directly to the area. It sets in about 5 minutes and cures in 1-3 hours.

-

JB Weld Plastic Weld

JB Weld Plastic Weld is specifically designed for plastic surfaces. Unfortunately, it doesn’t clear weld effectively. To use, clean the area, mix the components, and apply to the plastic. It cures in about 60 minutes for complete bonding.

-

JB Quik Plastic Bonder

JB Quik Plastic Bonder is a rapid-set adhesive for plastics. It won’t provide a clear weld effect. To use, apply directly from the tube, and it sets in about 20-30 minutes.

You should now have a good understanding of JB Weld varieties, including Clear Weld. In the next part, we’ll discuss prerequisites.

Prerequisites

What do you need to get started with JB Weld Clear Weld?

- JB Weld Clear Weld Epoxy: You’ll need JB Weld ClearWeld Quick Setting Epoxy. It’s crucial for strong bonds in various materials.

- Mixing Stick: A simple stir stick, like a craft stick or popsicle stick, works well. You need this to mix the epoxy thoroughly for a proper bond.

- Surface Cleaner: Use isopropyl alcohol (IPA) or acetone. Clean surfaces help the epoxy adhere better, ensuring a lasting connection.

- Plastic Applicator: Use a plastic putty knife to spread the epoxy. It allows for even application, which is vital for maximizing strength.

We’ve wrapped up the prerequisites for JB Weld Clear Weld here. Next up, we’ll look at the steps to prepare and apply.

Steps to Prepare and Apply JB Weld Clear Weld

Here are key steps to apply JB Weld Clear Weld efficiently.

-

Clean the Surface

Start by cleaning the surfaces you want to bond. Use a degreaser or isopropyl alcohol to remove dirt, oil, and grease. This creates a strong foundation for your adhesive. Parts can fail due to insufficient cleaning—trust me, it makes a difference!

Wipe the area dry; moisture can interfere with bonding. The surface must be free of contaminants for the best results. Take your time—this is crucial!

-

Mix the Epoxy

Next, mix equal parts of the JB Weld Clear Weld epoxy. Use a disposable container to pour the resin and hardener. Blend them thoroughly with a stir stick for about 30 seconds. Poor mixing can weaken the bond.

This epoxy has a quick setting time of about 5 minutes. Apply it quickly before it thickens. I always prepare my materials nearby—I’ve regretted delays in the past!

-

Apply the Epoxy

Apply the mixed epoxy directly to one surface using a small brush or toothpick for precision. This helps seal gaps, especially when filling holes. I’ve been down this road before; using too much can create messy results!

For best results, apply a thin, even layer. Avoid excess epoxy, which can create bubbles or weaken the hold. Remember, it sets quickly, so act promptly!

-

Join the Parts

Carefully press the parts together, ensuring proper alignment. JB Weld Clear Weld works well on both metal and plastic. Apply firm pressure to ensure a strong bond and remove any air gaps that could weaken the joint.

If excess epoxy spills out, wipe it away immediately with a cloth to keep your project tidy. Adjust the alignment as needed before it sets—once hard, it can’t be repositioned!

-

Wait for the Cure

Let the epoxy cure for at least 20 minutes before handling. For maximum strength, allow it to sit for 24 hours. Avoid applying stress to the joint during this time, as it can compromise the bond.

JB Weld Clear Weld typically cures fully within 24 hours, achieving impressive strength—about 3,960 psi! Patience is key for long-lasting results. JB Water Weld longevity is also remarkable, especially when used on non-porous surfaces like metal, plastic, glass, and PVC. With its resistance to water, chemicals, and temperature changes, JB Water Weld is a reliable solution for a wide variety of repairs that need to stand the test of time. Whether you’re fixing a leaky pipe, a cracked sink, or a broken glass ornament, JB Water Weld provides a durable, enduring seal that you can trust.

You should now have a good understanding of how to prepare and apply JB Weld Clear Weld. In the next part, we’ll discuss precautions.

Precautions

Let’s cover essential safety measures for using JB Weld.

- Ventilation: Work in a well-ventilated space to avoid inhaling fumes. Consider using a fan like Vornado for optimal results.

- Skin Protection: Always wear gloves! JB Weld can irritate your skin. Try 3M nitrile gloves for safe handling.

- Eye Safety: Use goggles to prevent splashes. It’s critical. Consider Uvex safety goggles.

- Disposal: Dispose of unused JB Weld properly. Follow local guidelines to reduce hazards and environmental impact.

Staying safe while using JB Weld is vital; please don’t skip these precautions!

We have now covered precautions for bonding products. Next, we will examine the various types of clear bonding products.

Types Of Clear Bonding Products

Let’s explore the different types of bonding products: clear epoxy adhesives, silicone adhesives, UV-curing adhesives, polyurethane adhesives, and cyanoacrylate adhesives.

-

Clear Epoxy Adhesives

Clear epoxy adhesives are strong and durable. They usually consist of two parts: resin and hardener. When mixed, they cure into a solid bond, making them ideal for metals, plastics, and glass. Can JB Weld clear weld? Absolutely, as epoxy can handle stress well, typically with tensile strengths exceeding 5,000 psi (34.5 Mpa).

-

Clear Silicone Adhesives

Clear silicone adhesives are flexible and waterproof. They’re great for sealing joints and gaps, resisting temperatures between -60°F and 400°F (-51°C to 204°C). Silicone adheres well to glass, metal, and ceramics, making it versatile.

-

Uv-curing Adhesives

UV-curing adhesives cure quickly when exposed to UV light, often setting in seconds. They’re effective on metal and glass surfaces but require direct UV exposure for complete curing.

-

Polyurethane Adhesives

Polyurethane adhesives are known for their strong bond and flexibility. They expand as they cure, effectively filling gaps. This feature makes them excellent for various substrates, like wood and metal, providing a strong hold.

-

Cyanoacrylate Adhesives

Also known as super glue, cyanoacrylate adhesives bond quickly to various materials. They work best on non-porous surfaces but may not perform well in extreme conditions. Still, they’re perfect for quick fixes due to their rapid setting time.

Factors Affecting JB Weld Clear Weld Performance

What factors can impact your JB Weld project’s effectiveness?

-

Temperature Conditions

Your application temperature is crucial. JB Weld performs best between 24°F (-4°C) and 300°F (149°C). Going outside this range can affect curing time and bond strength.

-

Surface Preparation

Clean surfaces ensure better adhesion. Metal, plastic, or ceramic must be free from grease, dirt, or moisture for a strong bond. Roughing smooth surfaces can improve grip as well.

-

Humidity Levels

High humidity can introduce moisture into the mix, weakening the bond and prolonging curing. Aim for humidity levels below 70% for the best results.

-

Application Technique

How you apply JB Weld matters. Use even pressure and the right amount—too much can cause drips, while too little can create weak spots. Precision helps achieve a strong bond.

-

Curing Time

Curing time varies by type; standard JB Weld takes about 15-24 hours. Allow the full time for maximum strength. Skipping this step often leads to weak repairs. Remember to carefully follow the instructions on the packaging in order to achieve the best results. It is important to note that the jb weld drying time can be affected by factors such as temperature and humidity. If you are working in a colder or more humid environment, it may take longer for the JB Weld to fully cure. Be patient and allow the recommended drying time for the strongest and most durable repair.

Common Issues You Might Encounter

Let’s look at unique technical challenges specific to JB Weld.

-

Improper Surface Preparation

JB Weld requires clean surfaces. Dirt and oil can weaken bonds. Clean with solvents first, and check for shine; it shouldn’t be there.

-

Inadequate Curing Time

I’ve faced this before. JB Weld needs time. Don’t rush it; allow 4-6 hours for initial set and full strength in 15-24 hours.

-

Mixing Ratio Errors

JB Weld mixes in a 1:1 ratio by volume. Get this wrong, and you’ll have weaker bonds. Measure carefully!

-

Incompatibility With Materials

JB Weld adheres to many materials, but not all. It won’t bond well with polyethylene. Test a small area first.

-

Exposure to Extreme Conditions

JB Weld can fail under extreme heat or cold. It withstands -40°F to 500°F (-40°C to 260°C), but frequent extremes can damage bonds.

Aftercare, Inspection, and Advanced Tips for JB Weld Clear Weld

Here’s important follow-up advice for your JB Weld projects.

Aftercare Tips

After applying the clear weld, let it cure undisturbed for a full 24 hours in a temperature range of 21°C to 27°C (70°F to 80°F). Avoid applying extreme heat or pressure during the initial curing phase. Keep the area clean and free from dust or moisture to ensure a strong bond.

Inspection Strategies

Inspect the joint for visible gaps or defects right after it sets, usually after 4 to 6 hours. Check that the bond feels firm and isn’t pliable; wiggle it gently if you’re unsure. Use a flashlight to detect undercuts or uneven layers not immediately visible to the naked eye.

Expert Tips

Here’s a pro tip based on my past projects: when mixing JB Weld, achieve a uniform blend by measuring equal parts (1:1 Ratio) with a scale. For large or critical repairs, apply heat of up to 80°C (176°F) after the initial cure to enhance bond longevity. Lastly, use a scraper to remove excess material before full curing for an aesthetically pleasing finish.

Benefits Of Using JB Weld Clear Weld

The main benefit of JB Weld Clear Weld is its strong bond. I used it for work when I needed to fix a cracked plastic part, and it held up like a champ! I was impressed by how well it bonded to the plastic and how clear the glue dried, making it almost invisible. Since then, I have used JB Weld Clear Weld for various other projects around the house and have been consistently pleased with the results. It’s amazing to discover the uses of JB Weld and how it can be used to repair and strengthen a wide range of materials.

It offers excellent versatility, adhering well to plastics, ceramics, and metals. You’ll appreciate its quick-setting formula, which cures in just 4-6 hours. It’s waterproof, making it ideal for indoor and outdoor projects. Plus, once cured, it’s sandable and paintable, allowing for seamless finishes.

Applications Of JB Weld Clear Weld

I’ve used JB Weld Clear Weld for quick fixes, but it has many applications, such as:

- Automotive Repairs: Clear Weld is ideal for fixing small cracks in headlights or taillights due to its transparency. It’s popular with do-it-yourself car enthusiasts.

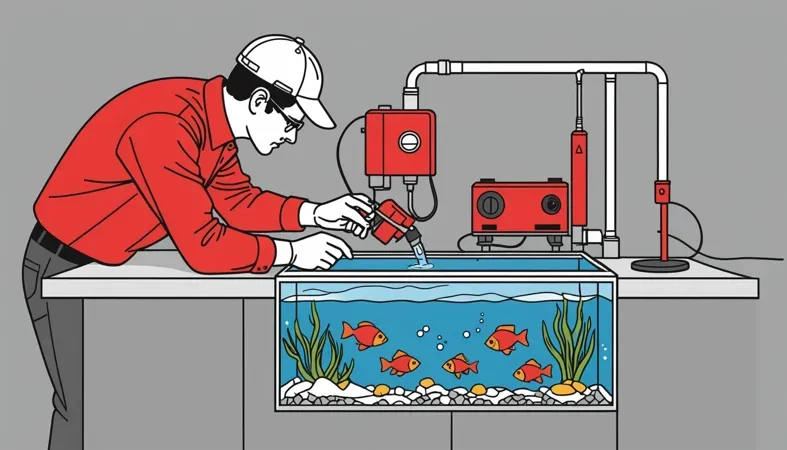

- Plumbing Seals: It seals leaks in PVC or rubber pipes effectively. People prefer it for quick plumbing jobs, especially in emergencies.

- DIY Crafts: Crafters use Clear Weld to bond glass, ceramics, or metal with no noticeable residue, making it very popular in the crafting community.

- Home Decor Repairs: Need to reattach decor items? This adhesive works wonders on ornamental pieces. It’s favored by homeowners for small home improvement tasks.

Other Options You Can Consider

If you’re looking for alternatives, consider epoxy adhesives like Gorilla Super Glue or Loctite Epoxy Clear. These products offer strong bonds similar to JB Weld, especially for plastic and metal repairs. They might be preferred when you need a quick set time, as Gorilla Super Glue sets in just 10-30 seconds.

You might also try Permatex Plastic Weld or 3M’s Hi-Temp Epoxy for specific situations. These options excel in high-temperature settings, making them ideal for automotive repairs. Having been through similar situations myself, I’ve found the right product can save time and yield great results.

Comparing JB Weld Clear Weld with Other Clear Adhesives

Understanding how JB Weld Clear Weld stacks up against other clear adhesives can help you make informed decisions for your projects. Here’s a detailed comparison.

| Adhesive Type | Setting Time | Max Temperature Resistance | Tensile Strength | Best Uses |

|---|---|---|---|---|

| JB Weld Clear Weld | 4-6 hours for handling24 hours for full cure | 500°F (260°C) | 3960 psi (27.3 Mpa) | Metal, plastic, ceramics, quick fixes |

| Gorilla Super Glue | 10-30 seconds | 200°F (93°C) | 4000 psi (27.6 Mpa) | Quick repairs on small items |

| Loctite Epoxy Clear | 20-30 minutes for initial set24 hours for full strength | 300°F (149°C) | 3500 psi (24.1 Mpa) | Metal to metal, ceramics |

| Clear Silicone Adhesive | 24 hours to fully cure | -60°F to 400°F (-51°C to 204°C) | Less than 2000 psi (13.8 Mpa) | Sealing joints, flexible projects |

As you can see, JB Weld Clear Weld offers a solid choice for durability and high-temperature resistance. If you need something that sets quickly, Gorilla Super Glue might be more suitable, though it may not withstand extreme conditions as well. Choose based on your project’s specific needs!

Frequently Asked Questions (FAQs)

Now let us look at some common questions I typically get asked.

How Good is JB Weld?

Yes, JB Weld is an exceptionally strong adhesive. It can bond most materials, providing a tensile strength of 3960 psi at full cure. This makes it ideal for metal, wood, ceramics, and more, ensuring your repairs hold up under stress.

What Does JB Weld Do?

JB Weld acts as a high-strength epoxy adhesive. It’s used to repair a wide range of materials, effectively sealing leaks and filling gaps. Whether it’s a crack in metal or plastic, JB Weld’s versatility makes it a go-to solution for DIY repairs.

What Does JB Weld Not Stick to?

JB Weld doesn’t stick well to certain surfaces, like Teflon, silicone, or any waxy plastics. These materials can hinder the bonding process, making your repairs less reliable. Always ensure surfaces are clean and roughened for the best adhesion.

How Big Of a Hole Can JB Weld Fix?

JB Weld can effectively fix holes up to 1 inch (2.54 Cm) in diameter. For larger holes, you may need to use additional filler material. Its outstanding bonding capabilities help ensure a durable and long-lasting repair.

Can JB Weld Hold Metal Together?

Yes, JB Weld can effectively hold metal together. It creates a strong bond when cured, making it great for automotive and machinery repairs. Proper surface prep and application enhance bond strength, maximizing the effectiveness of your repair.

For achieving a seamless finish in metalwork, understanding the techniques to weld edge joints can be crucial.

How Does JB Weld Work?

JB Weld works by combining two components: an epoxy resin and a hardener. When mixed, they create a chemical reaction that forms a tough, solid bond. Once fully cured, typically in 24 hours, it can withstand heat up to 550°F (287°C). It is crucial to consider safety measures during welding processes to protect oneself from hazardous fumes. Discover how to prevent inhaling welding fumes effectively.

What Should You Not Use JB Weld on?

Do not use JB Weld on areas that require flexibility or moving parts. It’s also not ideal for submerged applications such as fuel tanks or under-water pipes since it may not hold up to constant moisture or high pressure. Additionally, avoid using JB Weld on exhaust systems, as the extreme heat and rapid temperature changes can cause the bond to weaken or fail over time. While it may be a temporary fix in some cases, it’s not a permanent solution for high-heat applications. Always ensure you’re using the right adhesive or repair method that matches the specific environmental and mechanical demands of the repair.

Can JB Weld Clear Weld Be Sanded?

Yes, JB Weld Clear Weld can be sanded after curing. Typical cure time is 4 to 6 hours for handling and up to 24 hours for full strength. Once cured, you can sand it down for a smooth finish and improved aesthetics.

How Long Does It Take for JB Weld Clear Weld to Dry?

JB Weld Clear Weld takes about 4 to 6 hours to become tack-free. For a full cure and maximum strength, allow 24 hours. Don’t rush the process; proper drying time ensures a robust and durable bond.

Conclusion

We’ve made it to the end, and I hope it was helpful. We covered what JB Weld is, its types related to clear weld, prerequisites for use, preparation steps, precautions, types of clear bonding products, performance factors, common issues, aftercare tips, benefits, applications, and other alternatives. Each point gives you the info you need for successful bonding.

So, can JB Weld clear weld? In short, yes, it can. It’s effective for bonding surfaces like metal, plastic, and even some ceramics. I hope these welding tips prove valuable to you as you consider using JB Weld for clear applications.

To explore more insights and practical advice on welding techniques, check out What is Welding.

References

- ISO. (2017). ISO 3834: Quality Requirements for Fusion Welding of Metallic Materials. Geneva, Switzerland: ISO.

- Canadian Welding Bureau (CWB): https://www.cwbgroup.org

- American Welding Society. (2020). AWS C5.6: Recommended Practices for Gas Metal Arc Welding. Miami, FL: AWS.

Mark is a skilled welding engineer specializing in advanced metal joining technologies and process design. With a formal education in welding engineering and a background rooted in practical experience, Mark bridges the gap between theory and application. He is passionate about making technical concepts accessible, empowering welders to embrace innovation while mastering essential skills. Mark combines his scientific expertise with a commitment to supporting the welding community alongside his uncle, Joe.

Adhesive Applications, American Welding Society, Clear Weld, DIY, DIY Repairs, Epoxy Adhesive, Jb Weld, Surface Preparation, Welding, Welding Techniques, Welding Tips