Can You Weld Galvanized Pipe? Understanding Weldability and Techniques

Published on: April 7, 2025 | Last modified: March 4, 2025

By: Joe Carter

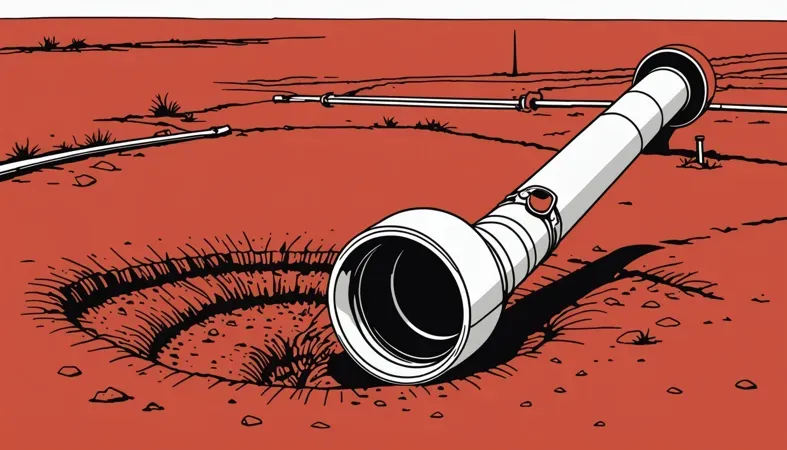

Galvanized pipe is steel pipe coated in a layer of zinc. This protects the metal from rust and corrosion.

One question I get asked a lot is, can you weld galvanized pipe? It’s crucial to know how to handle galvanized pipe because the zinc can release harmful fumes when heated. In my experience, understanding the weldability of galvanized steel is key to a successful project.

In this guide, we’ll explore the weldability of galvanized pipe, the different types of galvanized pipe, key steps for welding, factors that affect welding, and answers to common questions. So, if you’ve ever wondered how to weld galvanized pipe or if you can weld galvanized pipe to steel, you’re in the right place!

Contents

Can You Weld Galvanized Pipe?

Yes, you can weld galvanized pipe, but it’s trickier than regular steel. The zinc coating emits harmful fumes when heated, so take precautions. Use a good MIG welder with proper ventilation to ensure a clean weld.

What is Galvanized Pipe?

Galvanized pipe is steel coated with zinc to prevent corrosion. This process involves dipping the steel into molten zinc, creating a strong bond. Typically, ASTM A53 and ASTM F1083 are the standards for these pipes. They can withstand pressures of around 235 psi (1,620 Kpa) and last up to 50 years.

Now, regarding welding, many ask, “Can you weld galvanized pipe?” In my experience, it’s tricky. The zinc coating can emit harmful fumes, which is a major concern.

When I worked on a plumbing project, I used galvanized pipe for the entire system. It performed well due to its corrosion resistance. However, I wondered if you can weld galvanized pipe without issues. It’s crucial to learn how to weld galvanized pipe properly to avoid inhaling fumes and to ensure a solid connection.

Types Of Galvanized Pipe and Their Weldability

What are the types of galvanized pipe regarding their weldability?

-

Water Pipe

Water pipes transport water in residential and commercial settings. You can weld this type, but it’s tricky. To achieve a solid joint, clean the surface to remove the zinc coating, then use a MIG (Metal Inert Gas) welder set to the correct temperature.

-

Gas Pipe

Gas pipes carry natural gas to homes and businesses. Welding these pipes is possible, but caution is essential. Always purge with nitrogen before starting to prevent dangerous gases, and use ER70S-6 wire for strength. Achieving the right technique is key when working with delicate metals, so explore how to weld sheet metal for precision and safety.

-

Structural Pipe

Structural pipes support buildings and other structures. You can weld them, but special preparation is necessary. Grind off the galvanization before welding, then use a suitable flux-core wire for the best results. If you encounter any issues with surface damage during welding, you may find it useful to explore how to fix welding spatter.

-

Electrical Conduit

Electrical conduit protects wires from damage. Welding is possible, but it’s often unnecessary. Consider using connectors to join conduits instead. If you do weld, prepare surfaces by removing the coating and ensure proper ventilation.

-

Fencing Pipe

Fencing pipes create sturdy barriers around properties. You can weld fencing pipe successfully. Clean the joints thoroughly, use a stick welder, and avoid overheating to maintain the pipe’s strength.

We’ve wrapped up the various types of galvanized pipe and their weldability here. Next up, we’ll look at welding steps for galvanized pipe.

Steps to Weld Galvanized Pipe

Here are the steps for successfully welding galvanized pipe. Follow them carefully for the best results.

-

Prepare the Workspace

First, clear your workspace. Ensure it’s well-ventilated since welding galvanized pipe produces harmful fumes like zinc oxide. Aim for a ventilation rate of at least 80 cubic feet per minute (CFM). Keep flammable materials away; it’s common sense!

Lighting’s important too—adequate lighting helps you see what you’re doing. I once worked in a dim area and struggled to align my welds. Light it up and keep it organized!

-

Clean the Pipe Surfaces

Next, clean the surfaces of the galvanized pipe. Use a wire brush to remove the zinc coating within a 10 cm (4-inch) radius of the weld area. This step’s vital because welding over zinc can create weak spots. Clean it thoroughly—no shortcuts!

After brushing, use a solvent to remove grease or oil. I’ve seen welds fail due to leftover grime. Trust me, a clean surface is crucial for strong joints.

-

Set Up the Welding Equipment

Set up your welding equipment, paying attention to the settings. For MIG welding, use Argon or a 75/25 Argon-CO2 mix. Set the voltage between 20-30 volts based on the pipe thickness—thinner pipes need lower voltage and wire feed speed.

For stick welding, use a low-hydrogen electrode, like E7018, with the current set between 90-130 amperes. You want a smooth arc without spatter—this’ll make your job easier!

-

Choose the Right Welding Method

Decide on a welding method that suits your project. You can use MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas). MIG is quick and effective for thicker sections, while TIG is more precise but takes longer. If you’re a beginner, steel welding is a good starting point that can help you understand the basics of welding techniques and materials.

As you explore different welding techniques, it is crucial to understand how dangerous welding can be to ensure safety throughout the process.

Consider the environment: if you’re outdoors, you might prefer flux-cored wire for better wind resistance. For lighter work indoors, stick to solid wire. Choosing the right method makes a significant difference!

-

Weld the Joint

Now, it’s time to weld! Move the welding torch slowly along the seam at a consistent speed. For a solid weld, maintain a distance of about 0.5 cm (0.2 Inches) from the surface. This distance ensures thorough penetration that binds the pipe effectively.

Pay attention to your bead—aim for a smooth, even appearance. If the bead’s too convex or too concave, you might’ve messed up. I used to underestimate bead shapes, but I learned they’re key to a strong joint!

We covered the steps for welding galvanized pipe. Next, we will cover tips and techniques for successful welding.

Welding Tips and Techniques for Galvanized Pipe

To ensure successful welding of galvanized pipe, consider these advanced tips and techniques.

Use a Heat Sink

Heat sinking can help control temperature and prevent zinc from vaporizing prematurely. Use a copper plate to absorb excess heat while you weld, minimizing fume release.

Stacking Beads Technique

If you’re facing difficulty achieving a solid weld, try stacking beads. This method involves making multiple passes to build up strength and fill gaps, especially on thicker galvanized pipes.

Welding Position

- Flat Position: Easiest; gravity helps keep the bead consistent.

- Horizontal Position: Requires careful control; watch for sagging.

- Vertical Position: More challenging; practice helps improve results.

- Overhead Position: Most difficult; ensure strong grip to prevent dropping the torch.

Choosing the Right Filler Material

Selecting the right filler material is key to quality welds with galvanized pipe. Here’s a quick comparison of common fillers:

| Filler Material | Best Use | Weld Characteristics |

|---|---|---|

| ER70S-6 | General welding | Good strength; minimal spatter |

| ER70S-2 | Outdoors | Stable arc; better for windy conditions |

| 7018 | Structural welding | Strong welds; requires higher skill |

Utilizing these techniques can improve your welding results and ensure durability in your galvanized pipe projects. Good luck, and happy welding!

We covered welding tips, techniques, and considerations for galvanized pipe here. Next, we will cover factors influencing welding galvanized pipe.

Factors Influencing Welding Galvanized Pipe

What factors impact welding a galvanized pipe more than others?

-

Surface Preparation Quality

Clean surfaces matter. Dirt, grease, or zinc can weaken welds, leading to failures.

-

Welding Method Selection

Choose the right welding technique. MIG and Stick methods each have unique advantages with galvanized materials and require different skill sets.

-

Heat Control During Welding

Managing heat is crucial. Excessive heat can burn off zinc, causing porosity (Small Holes), weak welds, and health hazards. Use proper settings on your welder and monitor heat carefully.

-

Type Of Filler Material

The filler material affects the final weld quality. Using a compatible filler for galvanized pipe avoids issues and strengthens the joint.

-

Pipe Thickness

Thinner pipes need less heat. Different thicknesses change your approach, so adjust your techniques to ensure a strong fusion.

We covered the factors affecting welding galvanized pipe here. Next, we will cover frequently asked questions.

Frequently Asked Questions (FAQs)

Here are some questions I typically get asked about welding, particularly related to welding galvanized materials.

What Happens When You Weld Galvanized Pipe?

When you weld galvanized pipe, the zinc coating vaporizes and can produce harmful fumes. This process can lead to poor weld quality if not managed well, as the fumes may cause weld defects like porosity. Always use proper ventilation and wear a respirator when welding to protect your health.

Welding tasks often require technical knowledge and adhering to legal standards ensures the safety and integrity of structures. Explore the specifics of legally welding a car frame to ensure compliance with regulations.

Can You Weld Galvanized Pipe With a MIG Welder?

Yes, you can weld galvanized pipe with a MIG welder. MIG welding allows for a fast and efficient process, but it requires proper technique to avoid weld defects. Metal Inert Gas welding works best with low-voltage settings and suitable wire types to reduce spatter.

Is Galvanized Hard to Weld?

Yes, galvanized materials can be tricky to weld due to the zinc coating. The zinc can create weak spots and cause excessive spatter. Using the right welding techniques and pre-treating the metal can improve your success rate significantly.

Why Drink Milk Before Welding Galvanized?

Drinking milk before welding galvanized isn’t a common practice but some believe milk can help line your stomach and reduce the chance of nausea from zinc fumes. It’s not scientifically supported, but staying healthy and hydrated is always recommended.

Can Galvanized Pipe Be Welded?

Yes, galvanized pipe can be welded. You must remove the zinc coating from the areas to be welded to achieve a strong joint. Otherwise, the zinc will negatively affect the weld quality and strength. Proper knowledge of the techniques is crucial for achieving a strong weld, and you can enhance your skills by exploring how to weld pipe with 6010.

How to Weld Galvanized Pipe?

To weld galvanized pipe, clean the surface thoroughly to remove the zinc layer where you plan to weld. You can use a grinder or a wire brush. Then, choose an appropriate welding method, such as MIG or TIG, and ensure good ventilation while working. When working with zinc-plated steel, it is crucial to understand the challenges involved in welding zinc-plated steel.

Conclusion

We’ve gone through a lot, thank you for sticking it out. We covered the definition of galvanized pipe, different types and their weldability, steps to effectively weld galvanized pipe, factors that influence weld quality, and addressed some frequently asked questions. Each section gave you insight and clarity on the topic.

To sum it up, yes, you can weld galvanized pipe, but it requires careful consideration of preparation and technique, especially due to the zinc coating. Remember, the steps we discussed help ensure quality welds that are strong and rust-resistant. If you have any lingering questions about welding galvanized steel pipe or the techniques involved, don’t hesitate to ask.

For additional insights and resources on welding, check out What is Welding.

References

- American Welding Society. (2020). AWS Welding Handbook: Welding Science and Technology (Vol. 1). Miami, FL: AWS.

- American Welding Society. (2018). AWS D14.3: Specification for Welding Earthmoving and Construction Equipment. Miami, FL: AWS.

- American Petroleum Institute. (2018). API 1104: Welding of Pipelines and Related Facilities. Washington, DC: API.

Joe Carter is a retired welding professional with over 40 years of hands-on experience in the industry, spanning ship repair, structural welding, and even underwater projects. Joe is a master of MIG, TIG, and Stick welding. Passionate about mentoring the next generation of welders, Joe now shares his decades of expertise and practical insights to help others build rewarding careers in welding.

American Welding Society, Galvanized Pipe, Metal Fabrication, MIG Welding, Safety Precautions, Welding, Welding Equipment, Welding Techniques